There are two classes for odorization systems, vaporization and odorant injection style. Vaporization-style odorizers have limited applications, specifically low-flow and constant flow, where there is little gas flow variation. Here we discuss the injection-style odorizers.

Chemical Injection Odorization Systems

Chemical Injection Odorization Systems

Today, chemical injection systems odorize transmission pipelines, large cities, many medium-size loads, and even some small loads in particular applications. The injection occurs with either a pump or a drip method that injects a known odorant volume into the gas pipeline. The gas becomes odorized by adding small amounts of liquid odorant into the moving gas. In this odorizer style, a computer controller monitors the flow, which will vary the injection rate.

There are three odorant injection technologies worthy of mention:

Bourdon Tube

In a Bourdon-style odorizer, the odorant injection is controlled by a Bourdon tube triggered by a differential-pressure transmitter that senses the flow across an orifice plate. This style is not a common odorizer.

Drip Systems

Pipelines first used drip technology to odorize high-flow systems with slight flow variation when temperatures and pressures were stable. In these systems, a needle valve controls the odorant to drip into the gas stream. Unfortunately, the system required operator presence to monitor performance through a peephole because of the frequent clogging of the needle valve due to odorant viscosity, density variation, and odorant deposits.

Today, the modernized drip system is improved with updated measurement, computer controllers, and control electronics to create a precision dosing system capable of odorizing gas over a wide flow range. One modification includes integrating electronically operated valves that pulse on and off to permit the precise odorant amount through a drip tube. Changes in the gas flow and head pressure (due to odorant tank level variations) drive the valve operation.

The drip tube is in a measurement chamber equipped with an optical sensor that sends electrical pulses with each drop dispensed. Drop size is dependent on the mass of the droplet, the surface tension of the odorant, and the surface area of the drip tube tip. Surface tension is slightly reliant on odorant temperature, requiring a simple linear correction. Therefore, the odorant temperature is the only variable needed to calibrate the drop’s mass. This methodology of odorant metering is more direct than measuring volume and converting it to mass.

Electrically or Pneumatically Driven Pump

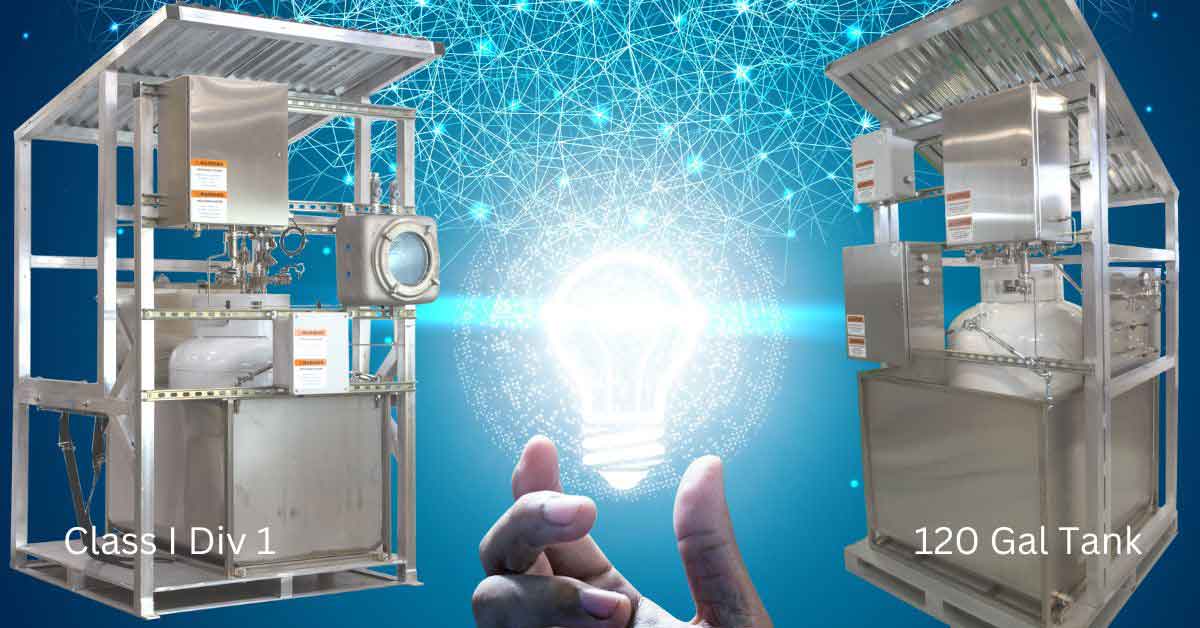

In another injection model, the odorant pumps into the pipeline gas stream through an electrical or pneumatic pump. An electronic system monitors the gas flow and controls the pump. Typically this design is suitable for odorizing gas flow rates above 175,000 SCFH.

Advantages and Disadvantages of Odorant Injection Odorizers

Odorant injection odorizers accurately track gas flow and odorize gas at wide flow variations. They also have built-in notifications or alarms for remote control capabilities. An office operator can instantly ascertain the dose rate, gas flow, odorant tank levels, and other pertinent details. (The GPL odorizer is indeed SMART, meaning it can receive alarms on a smartphone. Additionally, the GPL odorizer can be accessed and reprogrammed through smartphones, tablets, or computers.) Injection systems provide suitable documentation to demonstrate the proper odorization rate and give the operator proof of continuous odorization.

Odorant injection odorizers accurately track gas flow and odorize gas at wide flow variations. They also have built-in notifications or alarms for remote control capabilities. An office operator can instantly ascertain the dose rate, gas flow, odorant tank levels, and other pertinent details. (The GPL odorizer is indeed SMART, meaning it can receive alarms on a smartphone. Additionally, the GPL odorizer can be accessed and reprogrammed through smartphones, tablets, or computers.) Injection systems provide suitable documentation to demonstrate the proper odorization rate and give the operator proof of continuous odorization.

Like any electronic device, the disadvantage is that it is susceptible to lightning damage. Backup power, of course, is required for outages. If the electronics fail, the unit may become inoperative if parts are not readily available. Injection systems are usually not recommended for small load systems because there is too much time between doses for continuous odorization at minimum flows. Additionally, injection systems cost more than evaporative systems. Some manufacturers, like GPL Odorizers, have made great strides in overcoming the disadvantages noted here.

THANK YOU FOR YOUR INFORMATION. WE ARE TRYING TO EDUCATE OURSELVES BEFORE WE INSTALL NATURAL GAS INTO OUR HOME

We need 06 nos of Odorizer unit (Absorption type odorizer system)

Alam, If you need assistance, reach out to the sales team by dropping a message here – https://www.gasodorizer.com/contact-us/ . Thank you!