GPL Odorizers manufactures a unique odorization system that is a standalone, all-inclusive, turnkey, mobile (and portable) natural gas odorant injection system. The manufacturer offers custom modifications to these unique systems.

Mobile Odorization System

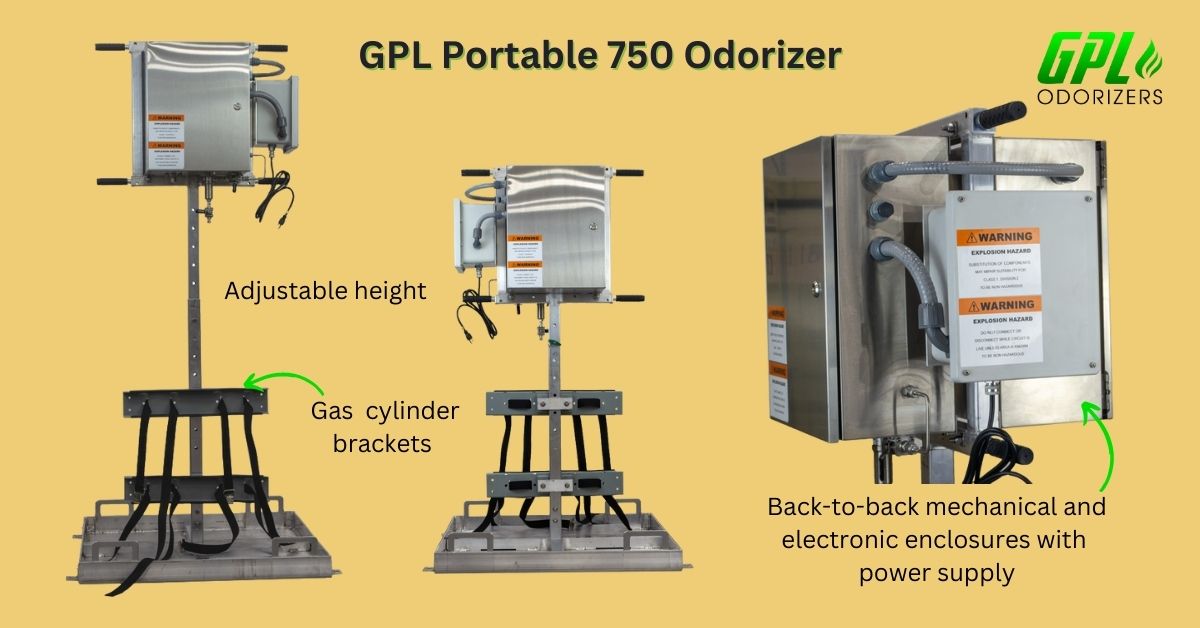

GPL-750-V-120-M/P Odorizer System

The GPL-750-V-120-M/P is an odorant injection system that is easy to install and moveable. The unit has a built-in metal pallet, which permits a forklift (or pallet jack) to transfer the entire system quickly. This design is not a temporary system. However, its built-in movability allows the user to move the unit to another application if needed. Its slim design, with a vertical tank orientation, requires a minimal footprint enabling efficient use of the area.

This odorizer system features a galvanized tin roof to protect it from the sun and reduces rain or snow in the containment vessel. The design offers easy access to the electrical enclosure, mechanical cabinet, power supply, and injection panel. The operator can remove the top if they need to replace the odorant tank.

The all-inclusive odorization system comprises the GPL 750 Odorizer, an industry-leading PLC, a 120-gallon ASME odorant tank, and a containment skid on an integrated aluminum pallet. Although not pictured here, it also includes the GPL 100 Flow Meter and pipeline tap assembly kit (comprising a sonic muffler, dielectric fitting, blow-down valve, and pipeline shut-off valve).

GPL-750-V-60-ClID1-M Odorization Systems

The GPL-750-V-60-ClID1-M (unit is in the banner image-left side) is similar in scope to the GPL-750-V-120-M/P. The unit has a 60-gallon odorant tank, and the electronics are housed in a Class I Division 1 hazardous classification (rather than Cl1 Div2). With a few other modifications.

Turnkey Odorization System Installation

Installation is straightforward:

- Set the unit on a level pad (end-user supplied).

- Bolt down the rig (bolt holes built into the base).

- Fill the odorant tank.

- Connect the GPL 750 odorizer from the drip chamber to the pipeline using the pipeline tap assembly kit.

- Connect the GPL 100 flow meter to the pipeline.

- Connect blanket gas to the injection panel.

- Turn on the power.

- Follow simple start-up instructions provided by GPL Odorizers.

Download the GPL-750-V-120-P/M flyer.

Custom Odorization Solutions

GPL Odorizers understands that most odorization applications are unique. Rather than turning out cookie-cutter natural gas odorizers, we design and manufacture systems to satisfy the end-user’s needs. Among some of the custom solutions are:

- Temporary odorization units

- Integrating an odorizer system in a fiberglass building to protection and security

- Tanks and containment skids in various sizes

- Pickling units

- Mobile systems such as the standalone unit on this page (capable of being moved)

- Portable systems offering quick and easy moveability

Contact us if you have an odorant injection challenge and want a quote on a GPL Odorizers’ standard or custom unit. If you need a portable solution, check out GPL 750 Portable Odorizer.